Researchers at the University of Adelaide have innovated a method to convert polyethylene waste into valuable chemicals using light-driven photocatalysis and solar energy, paving the way for sustainable waste management and contributing to a circular economy.

Table of Contents

ToggleNew Recycling Method Could Make Polyethylene Waste a Thing of the Past

An international team of scientists undertaking fundamental research has discovered a method to use polyethylene waste (PE) as a raw material. They have successfully transformed it into valuable chemicals through a process called light-driven photocatalysis.

“We have upcycled polyethylene plastic waste into ethylene and propionic acid with high selectivity using atomically dispersed metal catalysts,” said Professor Qiao.

“An oxidation-coupled room-temperature photocatalysis method was used to convert the waste into valuable products with high selectivity. Nearly 99 percent of the liquid product is propionic acid, alleviating the problems associated with complex products that then require separation. Renewable solar energy was used rather than industrial processes that consume fossil fuel and emit greenhouse gases. This waste-to-value strategy is primarily implemented with four components, including plastic waste, water, sunlight, and non-toxic photocatalysts that harness solar energy and boost the reaction. A typical photocatalyst is titanium dioxide with isolated palladium atoms on its surface.”

Addressing Plastic Waste Challenges

Most of the plastics used today end up being discarded and accumulated in landfills. PE is the most widely used plastic in the world. Daily food packaging, shopping bags, and reagent bottles are all made from PE. It is also the largest proportion of all plastic waste and primarily ends up in landfills, posing a threat to the global environment and ecology.

“Plastic waste is an untapped resource that can be recycled and processed into new plastics and other commercial products,” said Professor Qiao.

“Catalytic recycling of PE waste is still in early development and is practically challenging because of chemical inertness of polymers and side reactions arising from structural complexities of reactant molecules.”

Potential Impact and Future Applications

Current chemical recycling for PE waste is operated at high temperatures greater than 400 degrees centigrade that yield complex product compositions.

Ethylene is an important chemical feedstock that can be further processed into a variety of industrial and daily products, while propionic acid is also in high demand owing to its antiseptic and antibacterial properties.

The team’s work aims to address contemporary environmental and energy challenges, contributing to a circular economy. It will be of use in further scientific research, waste management, and chemical manufacturing.

“Our fundamental research provides a green and sustainable solution to simultaneously reduce plastic pollution and produce valuable chemicals from waste for a circular economy,” said Professor Qiao.

“It will inspire the rational design of high-performance photocatalysts for solar energy utilization and benefit the development of solar-driven waste upcycling technology.”

Hermit crabs are ‘wearing’ our plastic rubbish

The vast majority of the items the researchers saw the hermit crabs using in the photographs were made of plastic

Hermit crabs all over the world, which scavenge shells as armour for their bodies, are turning increasingly to plastic waste instead.

The conclusion is based on analysis of photos, taken by wildlife enthusiasts, and published online.

Scientists said they were “heartbroken” to see the extent to which the animals were living in our rubbish.

They said two-thirds of hermit crabs species were pictured in “artificial shells” – items that humans discarded.

The study used social media and photo-sharing websites, as one of the researchers Marta Szulkin, an urban ecologist from the University of Warsaw, explained: “We started to notice something completely out of the ordinary.

“Instead of being adorned with a beautiful snail shell, which is what we’re used to seeing – they would have a red plastic bottle cap on their back or piece of light bulb.”

She and her colleagues, Zuzanna Jagiello from the University of Warsaw and Łukasz Dylewski, from Poznan University of Life Sciences, found a total of 386 individuals using artificial shells – mainly plastic caps.

“According to our calculations, 10 out of the 16 species of land hermit crabs in the world use this type of shelter and it’s been observed in all tropical regions of the Earth,” Prof Szulkin explained.

It isn’t yet clear whether these materials are harmful – or perhaps even helpful – for the small, vulnerable crustaceans.

Fighting over plastic

This internet-based ecological study, revealed that this use of artificial shells is a “global phenomenon”.

“We saw it in two-thirds of all terrestrial hermit crab species,” said Prof Szulkin. “That’s what we could identify just by using pictures taken by tourists.”

The researchers say the findings open up new questions about how these coastal crustaceans interact with and use plastic. As well as understanding whether it causes them any harm, the scientists want to work out how it might affect their evolution.

This whole group of crabs have adapted to scavenge and use discarded snail shells to protect their fragile bodies. And when those shells are in short supply, the crabs will fight over them.

What we don’t know is how much the element of novelty might affect them – and whether the crabs will fight over artificial plastic shells,” explained Prof Szulkin.

The researcher said that the natural snail shells were in decline, so she suspected it might be becoming easier for the animals to find an artificial alternative. And lighter, plastic ‘shells’ might even help smaller, weaker crabs to survive because they are easier to carry.

There is certainly a great deal of plastic in the marine environment for the animals to choose from. A recent study that attempted to quantify the scale of plastic pollution estimated that at least 171 trillion pieces of plastic are now floating in our oceans.

That could nearly triple by 2040 if no action is taken, experts have warned.

Mark Miodownik, who is professor of materials and society at University College London told the BBC that there was a lesson for humans in these images. “Just like the hermit crabs,” he said, “we should be reusing plastics much more, instead of discarding it.”

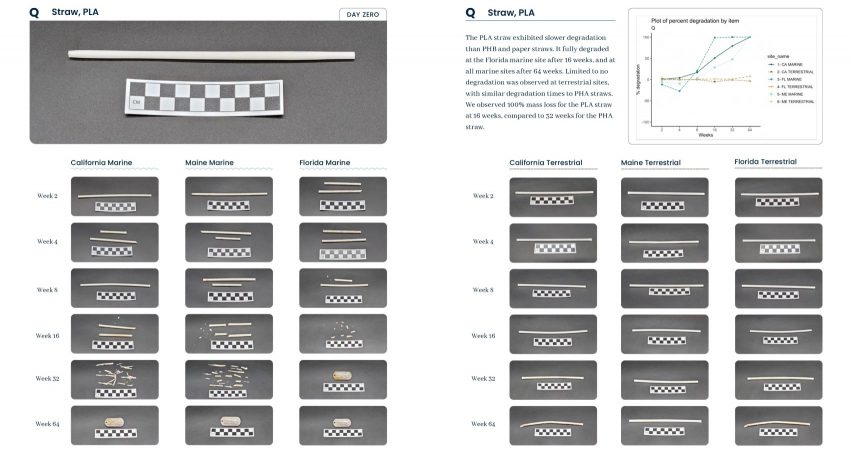

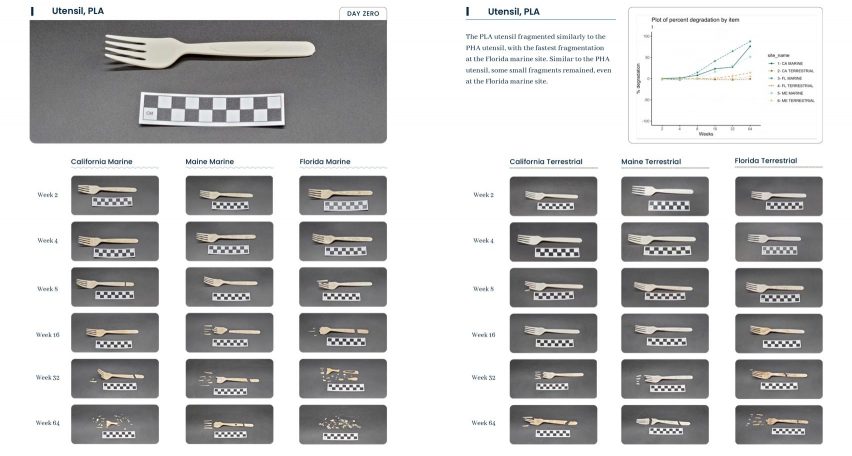

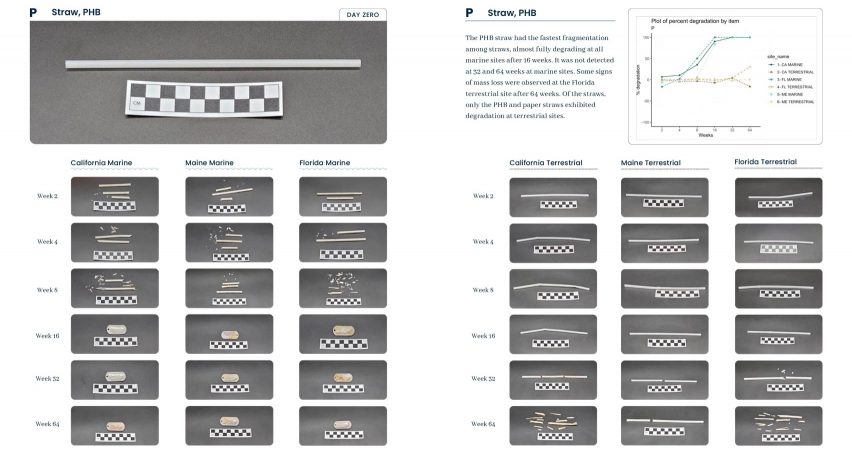

The study found that some bioplastic packaging did not decompose after being buried underground for more than a year, regardless of the climate and soil conditions.

Other common types of bioplastic packaging showed little or no signs of degradation after 64 weeks in soil, with forks, bottles and tampon applicators among them.

Lisa Erdle, director of science and innovation at 5 Gyres, said the results prove that bioplastics are not a one-size-fits-all fix for plastic pollution, despite what their biodegradable labelling might lead people to assume.

“There is no silver bullet solution for the plastics crisis,” she said. “Instead, we need targeted solutions that address each sector of plastic use in society, from textiles and tyres to agriculture and electronics.”

However, Erdle suggested that bioplastics can “offer potential to mitigate harm in specific cases”.

“There are opportunities for upstream innovations across all sectors,” she explained. “And for some sectors, bioplastics offer an alternative to traditional plastics.”

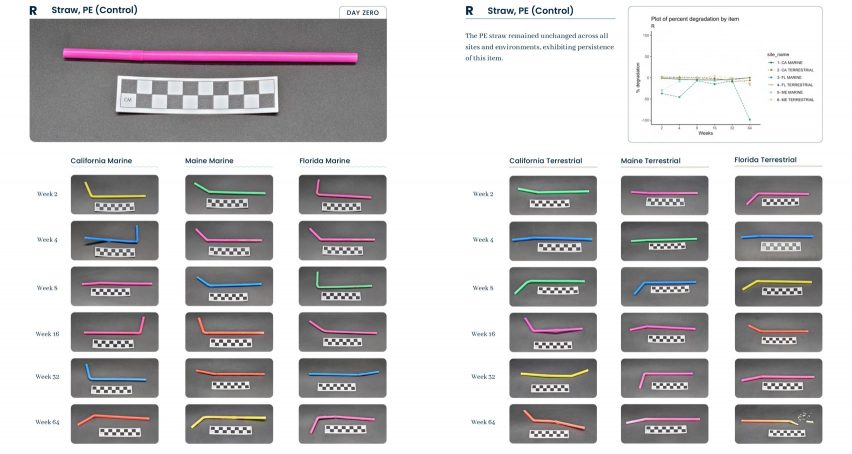

The study backs up this claim. Among the 22 object types tested were three made from polyethene, or PE, a thermoplastic derived from petroleum. Film, forks and straws made from PE failed to degrade at any test sites, either terrestrial or marine.

While the bioplastics all degraded faster, some types were significantly more successful than others.

While the PLA straws failed to degrade in soil, alternatives made from polyhydroxybutyrate (PHB) – a bioplastic produced by bacteria – biodegraded either fully or partially at all test sites.

The results from different types of bioplastic film were equally varied.

PLA fragmented far slower than polyhydroxyalkanoate (PHA), another bioplastic produced by bacteria. Fragments of PLA remained at all test sites after 64 weeks, while the PHA was no longer detectable at the Florida marine site after just eight weeks.

The test objects also included paper straws, which were found to be similar to PHB in terms of degradation, and bamboo forks, which were the slowest to degrade of all the utensils.

According to Marcus Eriksen, co-founder and researcher at 5 Gyres, the results prove the need for greater transparency and clearer messaging in how disposable products are used and marketed.

Researchers engineer bacteria that eat plastic, make multipurpose spider silk

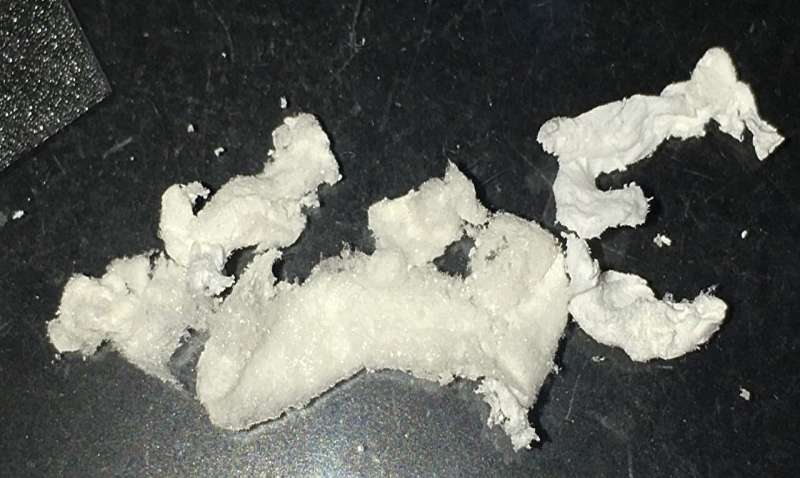

Silk proteins generated by bacteria engineered to convert polyethylene into this mult

Move over Spider-Man: Researchers at Rensselaer Polytechnic Institute have developed a strain of bacteria that can turn plastic waste into a biodegradable spider silk with multiple uses.

Their new study, published in Microbial Cell Factories, marks the first time scientists have used bacteria to transform polyethylene plastic—the kind used in many single-use items—into a high-value protein product.

That product, which the researchers call “bio-inspired spider silk” because of its similarity to the silk spiders use to spin their webs, has applications in textiles, cosmetics, and even medicine.

“Spider silk is nature’s Kevlar,” said Helen Zha, Ph.D., an assistant professor of chemical and biological engineering and one of the RPI researchers leading the project. “It can be nearly as strong as steel under tension. However, it’s six times less dense than steel, so it’s very lightweight. As a bioplastic, it’s stretchy, tough, nontoxic, and biodegradable.”

All those attributes make it a great material for a future where renewable resources and avoidance of persistent plastic pollution are the norm, Zha said.

Polyethylene plastic, found in products such as plastic bags, water bottles, and food packaging, is the biggest contributor to plastic pollution globally and can take upward of 1,000 years to degrade naturally. Only a small portion of polyethylene plastic is recycled, so the bacteria used in the study could help “upcycle” some of the remaining waste.

Pseudomonas aeruginosa, the bacteria used in the study, can naturally consume polyethylene as a food source. The RPI team tackled the challenge of engineering this bacteria to convert the carbon atoms of polyethylene into a genetically encoded silk protein. Surprisingly, they found that their newly developed bacteria could make the silk protein at a yield rivaling some bacteria strains that are more conventionally used in biomanufacturing.

The underlying biological process behind this innovation is something people have employed for millennia.

“Essentially, the bacteria are fermenting the plastic. Fermentation is used to make and preserve all sorts of foods, like cheese, bread, and wine, and in biochemical industries it’s used to make antibiotics, amino acids, and organic acids,” said Mattheos Koffas, Ph.D., Dorothy and Fred Chau ʼ71 Career Development Constellation Professor in Biocatalysis and Metabolic Engineering, and the other researcher leading the project, and who—along with Zha—is a member of the Center for Biotechnology and Interdisciplinary Studies at Rensselaer.

To get bacteria to ferment polyethylene, the plastic is first “predigested,” Zha said. Just like humans need to cut and chew our food into smaller pieces before our bodies can use it, the bacteria have difficulty eating the long molecule chains, or polymers, that comprise polyethylene.

In the study, Zha and Koffas collaborated with researchers at Argonne National Laboratory, who depolymerized the plastic by heating it under pressure, producing a soft, waxy substance. Next, the team put a layer of the plastic-derived wax on the bottoms of flasks, which served as the nutrient source for the bacteria culture. This contrasts with typical fermentation, which uses sugars as the nutrient source.

“It’s as if, instead of feeding the bacteria cake, we’re feeding it the candles on the cake,” Zha said.

Then, as a warming plate gently swirled the flasks’ contents, the bacteria went to work. After 72 hours, the scientists strained out the bacteria from the liquid culture, purified the silk protein, and freeze-dried it. At that stage, the protein, which resembled torn-up cotton balls, could potentially be spun into thread or made into other useful forms.

“What’s really exciting about this process is that unlike the way plastics are produced today, our process is low-energy and doesn’t require the use of toxic chemicals,” Zha said. “The best chemists in the world could not convert polyethylene into spider silk, but these bacteria can. We’re really harnessing what nature has developed to do manufacturing for us.”

However, before upcycled spider silk products become a reality, the researchers will first need to find ways to make the silk protein more efficiently.

“This study establishes that we can use these bacteria to convert plastic to spider silk. Our future work will investigate whether tweaking the bacteria or other aspects of the process will allow us to scale up production,” Koffas said.

“Professors Zha and Koffas represent the new generation of chemical and biological engineers merging biological engineering with materials science to manufacture ecofriendly products. Their work is a novel approach to protecting the environment and reducing our reliance on nonrenewable resources,” said Shekhar Garde, Ph.D., dean of RPI’s School of Engineering.

The study was conducted by first author Alexander Connor, who earned his doctorate from RPI in 2023, and co-authors Jessica Lamb and Massimiliano Delferro with Argonne National Laboratory.

Credit for post: phys.org